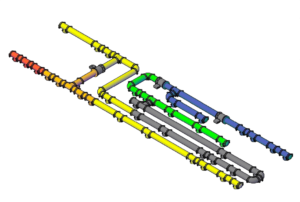

A Thermal Gradient Header (TGH) is a piping framework and standardized control sequence that functions as a smart hub for the transfer of thermal energy. It has a continuous pipe filled with water or glycol which has a hot end and a cold end with a gradient of variable temperature zones in between. Thermal energy is transferred within a zone or from zone to zone based on building demand.

A Thermal Gradient Header (TGH) is a piping framework and standardized control sequence that functions as a smart hub for the transfer of thermal energy. It has a continuous pipe filled with water or glycol which has a hot end and a cold end with a gradient of variable temperature zones in between. Thermal energy is transferred within a zone or from zone to zone based on building demand.

The TGH integrates and also separates systems based on supply and return of fluid temperatures. This is independent of whether they are used for ‘heating’ or ‘cooling’ or both. The TGH allows HVAC engineers to use standard HVAC equipment and components to develop designs that provide the most efficient and cost-effective method to manage thermal energy resources in and around a building.

The Thermal Gradient Header difference. Our engineers went back to first principles and came up with two innovative piping arrangements – our original design, a ‘Thermenex System’, is patented and solves the temperature optimization problem. Our newer design, called the Single-Primary, Dual-Secondary piping arrangement is patent pending and simplifies the control logic.

Single Variable Primary, Dual Variable Secondary (SVPDVS) Piping Arrangement. The TGH utilizes an innovative hydronic de-coupler arrangement on both the heating and cooling piping that automatically optimizes two heating water temperatures and two cooling water temperatures from a central heat pump plant. The control logic maximizes efficiency by continuously minimizing heat pump lift during either part-load or full-load operation.

Now simply called, TGH, the two systems together provide a high-performance standard piping framework with standard proven control logic. Unlike other water-based solutions, a TGH does not distinguish between loads and sources. The TGH’s six temperature zones optimize the performance of standard, non-proprietary HVAC equipment under all the variable conditions encountered by a typical large building. The TGH logic automatically controls to the lowest energy input, sometimes that is passive heat exchange, sometimes it is active with a heat pump, and sometimes it is both. See how a TGH works.

Sustainable: Minimizes consumption of non-thermal resources (gas and electricity) by optimizing all thermal resources first which significantly reduces greenhouse gas emissions.

Efficiency: Operating passively whenever possible while delivering multiple temperatures to dynamically optimize the heat pumps.

Simplicity: Because all loops are connected to the header, heating/cooling switch-over can be accomplished very easily to reduce the number of components required.

Resiliency: With all systems interconnected there is inherent resiliency and redundancy as the total TGH system will keep working even when some components fail.

Capital Cost: Individual components can be configured to provide heating, cooling and by default heat reclaim, resulting in fewer components needed for a building.

Life-cycle Cost: There is no requirement for proprietary equipment. The system employs standard components that are less expensive to replace. The header pipe will last the life of the building.

Guarantee: If the TGH doesn’t function properly (assuming our product application guide is followed), Thermenex will make the necessary corrections – backed by a $5,000,000 general liability insurance policy.