The experts at Thermenex have proven that the application of TGH technology is a cost-effective way to achieve a building that has no wasted energy and minimum destroyed exergy (energy from high quality external resources). Our TGH compact piping framework allows an engineer to design a solution with the minimum in HVAC component utilization, energy use, and carbon emissions.

Achieving thermal efficiency using a pipe with hot water at one end and cold water at the other may seem counter intuitive.

The obvious question: Wouldn’t heating and cooling mix?

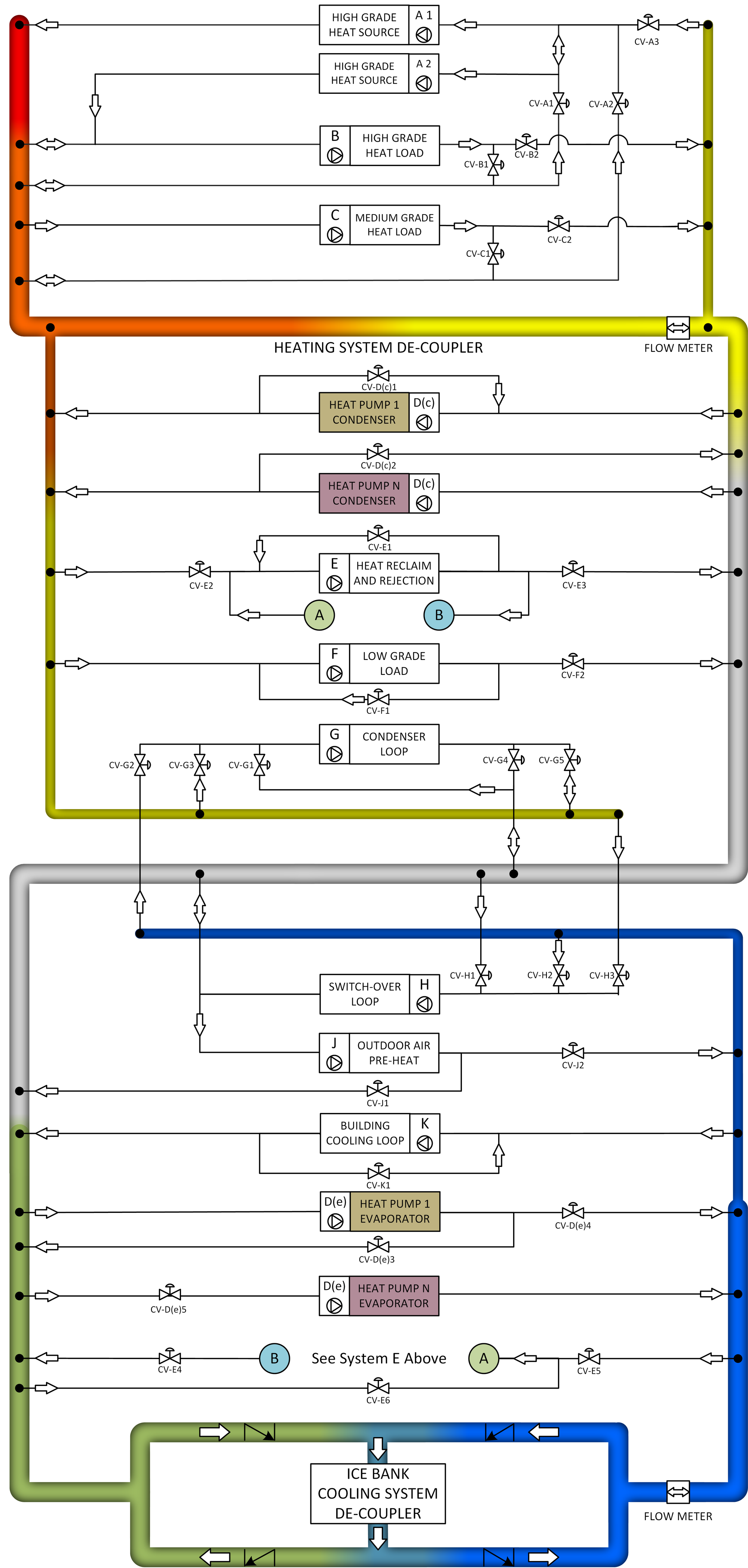

Thermenex has the answer: The TGH has six distinct temperature regions that are separated using a simple hydronic design so they do not mix. This enables matching of source temperatures with the variable load requirements of a building. Conventional systems have only two temperatures – one hot and one cold. All the various heating systems mix to the one hottest supply temperature and the various cooling systems mix to the one coldest supply temperature. TGH Systems don’t mix, and thus they are more efficient than conventional systems. Contact us and find out how a TGH can benefit your next project.

Thermenex has turned a simple pipe into a heating and cooling thermal energy transfer hub. Engineers know high-performance, sustainable HVAC systems in large buildings require the integration of multiple systems, functioning in variable conditions, making them inherently more complex.

Engineers now have a choice. They can develop their own one-off hydronic configuration and control sequences, striving to approach optimum performance, or they can choose to design a TGH system that is based on the theoretical optimum performance with a standardized proven control sequence.

Truly sustainable buildings, defined below, must first optimize their own inherent thermal energy.

- The first stage of heating shall be provided by building recovered thermal energy.

- No external resources are to be used for heating at the same time heat is being rejected.

- Heating systems are to return the lowest fluid temperature.

- Cooling systems are to return the highest fluid temperature.

- Large exhaust and relief air systems must be equipped with active heat recovery.

- Heat reclaim is to take precedence over air-side and water-side economizing.

- Heat reclaimed from all sources must be holistically available for all loads.

- Maximize use of ‘passive’ heat transfer of thermal energy from sources to loads.

We have a patent on directly connecting a heating loop with a cooling loop using a single pipe.

This obviously applies to the entire header, specifically to three of the sub-system connections allowing both passive reclaim of waste heat and, active reclaim using a heat pump, or both simultaneously.

We are patent pending on the Single-Primary, Dual-Secondary piping arrangement which allows the automatic and dynamic optimization of a heat pump plant efficiency by preferentially loading the heat pumps to their highest efficient state. All controlled with a single chilled water set point without control valves or logic required.